Custom 3D Printers

While I was going to school, and also taking care of my Dad who was diagnosed unexpectedly with Stage 4 small cell cancer, we started to do projects together to keep our minds sharp. The following is about our custom DLP/UV LED 3D Printer.

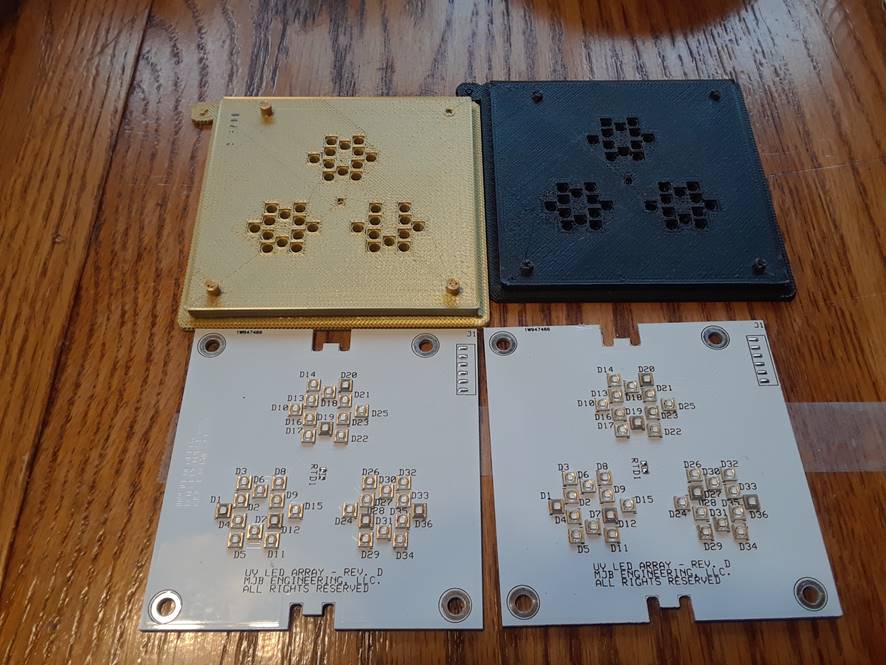

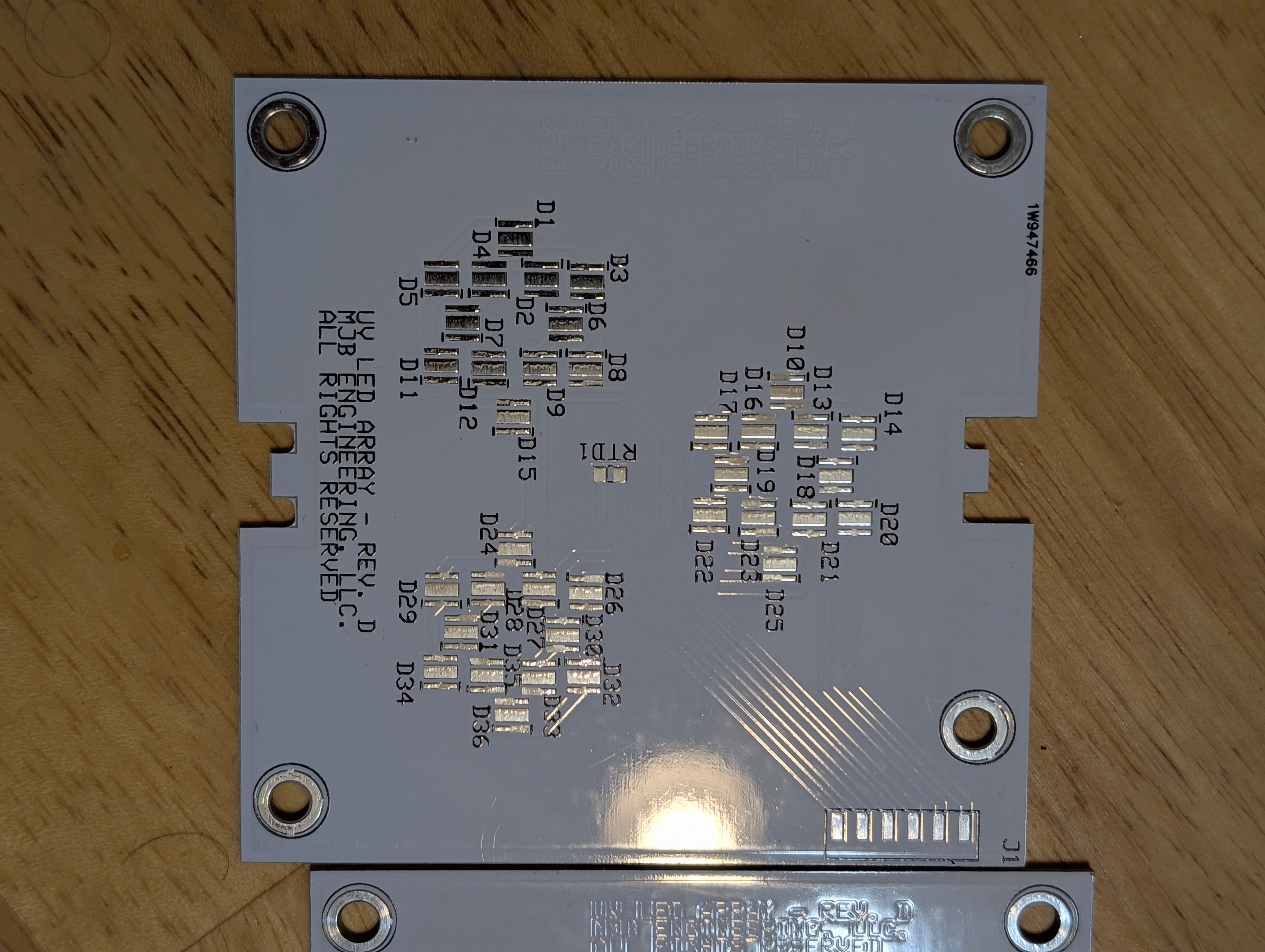

The UV LED we drew up in PCB CAD, and sent the job over to our friend in the UK who operates and owns a UV LED business. We got our first prototype UV LED array. The idea behind this is, (beyond the difficulty of sourcing a reliable Chinese made monochrome LCD who makes it consistently, or for years) you're able to interchange the UV LED array, with a collumator with a Digital Light Processing Projector. It would require approximately, 2,000 to 3,000 lumens. This would be actually be a more cheap solution than to utilize our UV LED array / lens collumator. I sourced a projector from an office lidquiation sale for about $100. It was 1080p resolution, capable of displaying the appropriate cross sections for each layer within the resin vat.

This we had intended to sell as kits, where you had the custom UV LED PCB available to purchase, or you could source your own projector and have a DIY, accurate, resin 3D printer. We had developed a mechanism to hold the aluminum build plate, that was similar to some designs we actually saw at the time (circa 2017) for sale, where quite similar.

Above you can see, it is simply a sphere with a M5 bolt going through it. The idea, is that you tighten the nut on the top end, and that tightens a screw fixing the sphere in place, within a cube. This is mechanically, a self-leveling mechanism for a flat build surface where you project light, and print resin plastic that sticks onto the flat aluminum build surface, which would be at the end of that M5 bolt, essentially. You would untighten the mechanism, jog the Z axis down gently at a slow speed, and then once it is at Z axis zero, you may tighten the nut in the mechanism, and set zero in your software. Then the build surface is level the vat and the vat film, and you'd be ready to go.

Here is an example, the idea was to utilize LinuxCNC which is an open source controller. You would technically run it off a laptop, or maybe another low power device like a Raspberry Pi. The software ingests .STL files, and creates cross sections, or convert it into workable machine G-code in conjunction with what would need to displayed on the Projector, or the UV LED LCD. The UV LEDs, sit below the monochrome LCD, providing a UV back light at ~425nm, and the LCD crystal screen, providing the image cross section shape, projecting the UV LED light specifically in that shape, to the aluminum build plate.

We went ahead and created all the pieces of the machine to hold the Z-axis, vat, and all that on DesignCad 3D MAX by IMSI. We went to a shop online, to get the pieces cut out in acrylic. This is reminiscient of one of our first 3D printers, which had a mostly acrylic frame, with long M8 bolts as reinforcement. With a FDM machine, you can get away with utilizing acrylic, but it is very brittle and not a very strong material. You would see vibrations from that frame translate into the print, but you don't need to worry about that with a resin printer, due to it moving a lot less, mechanically.

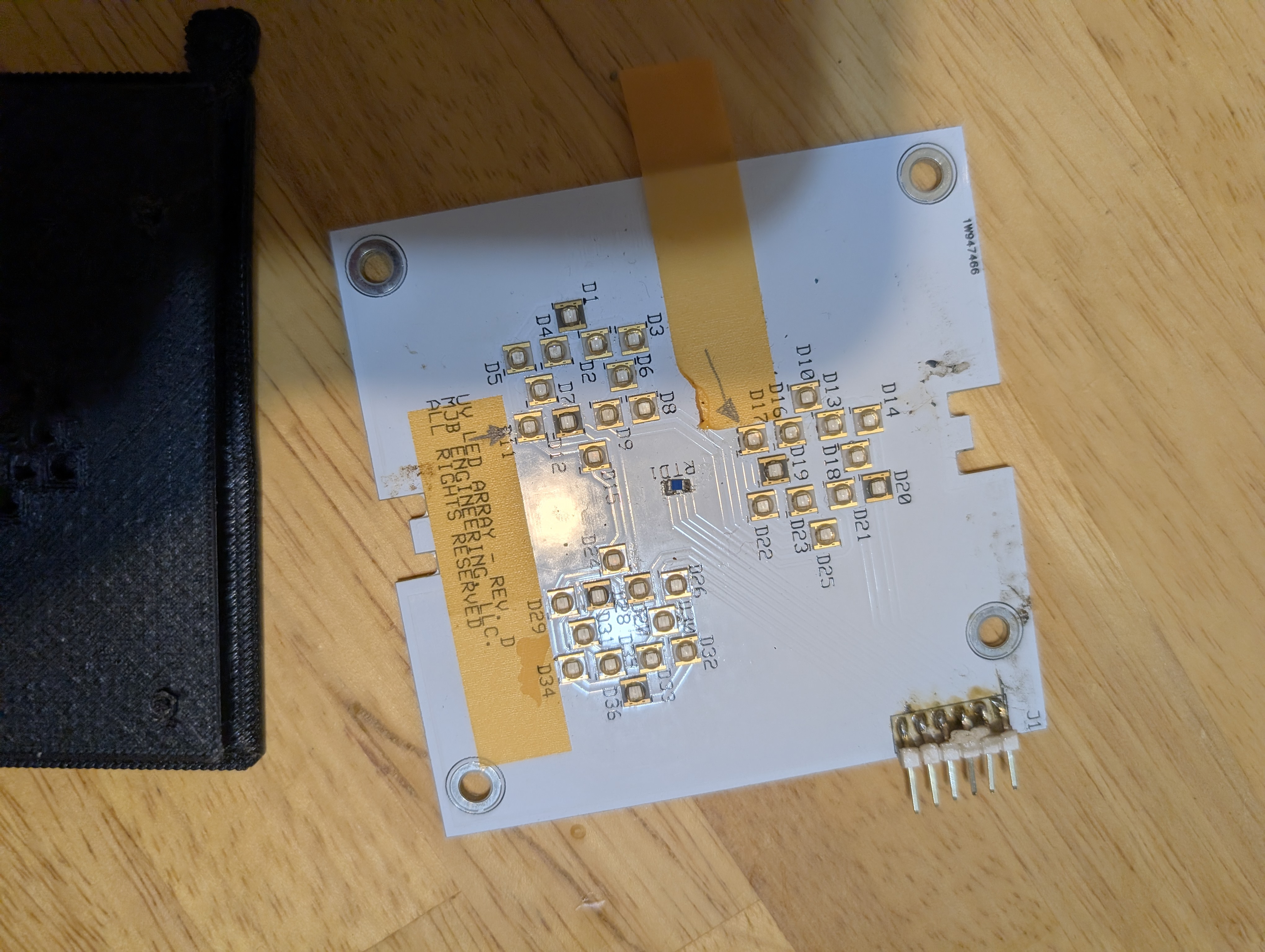

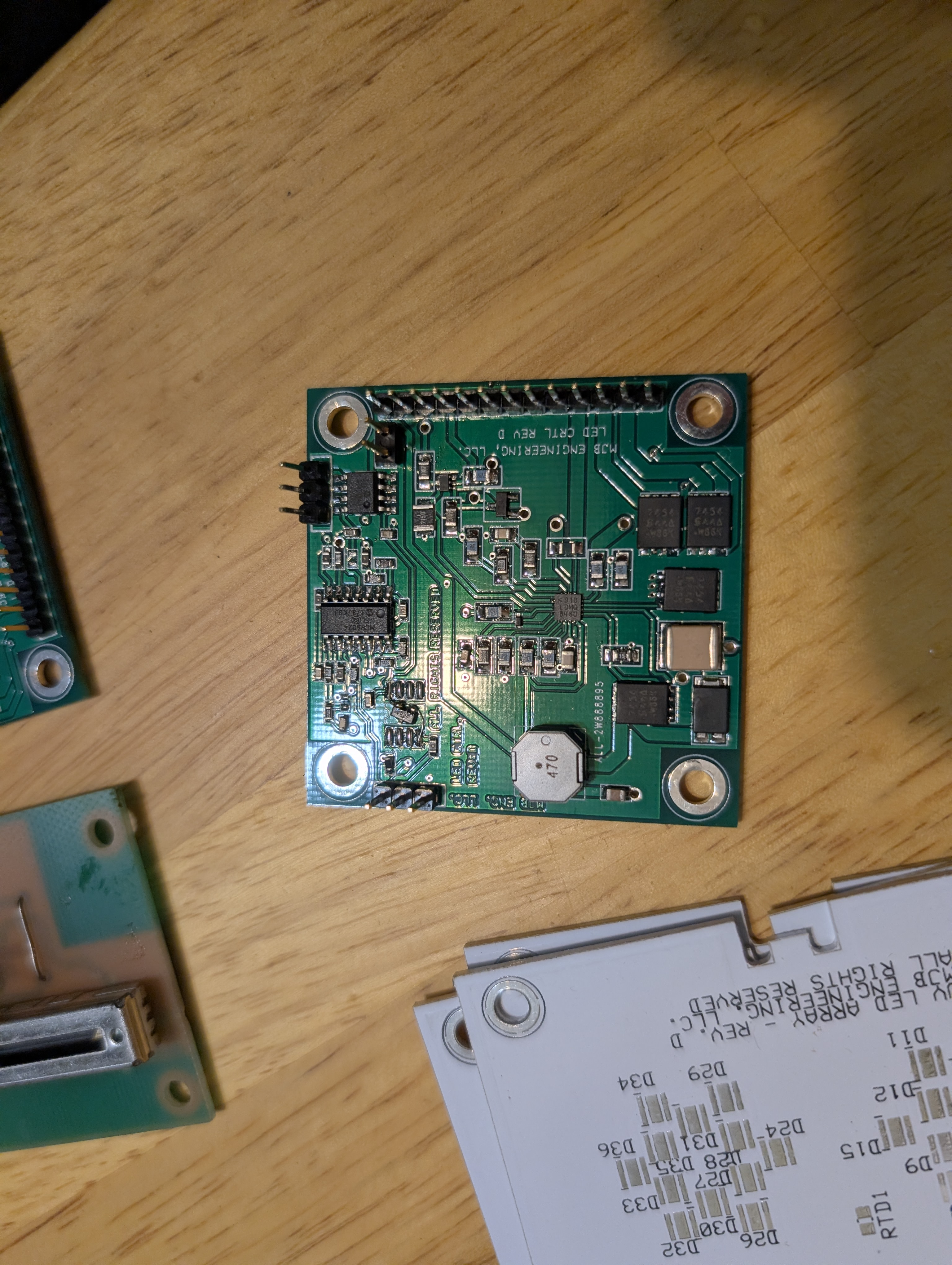

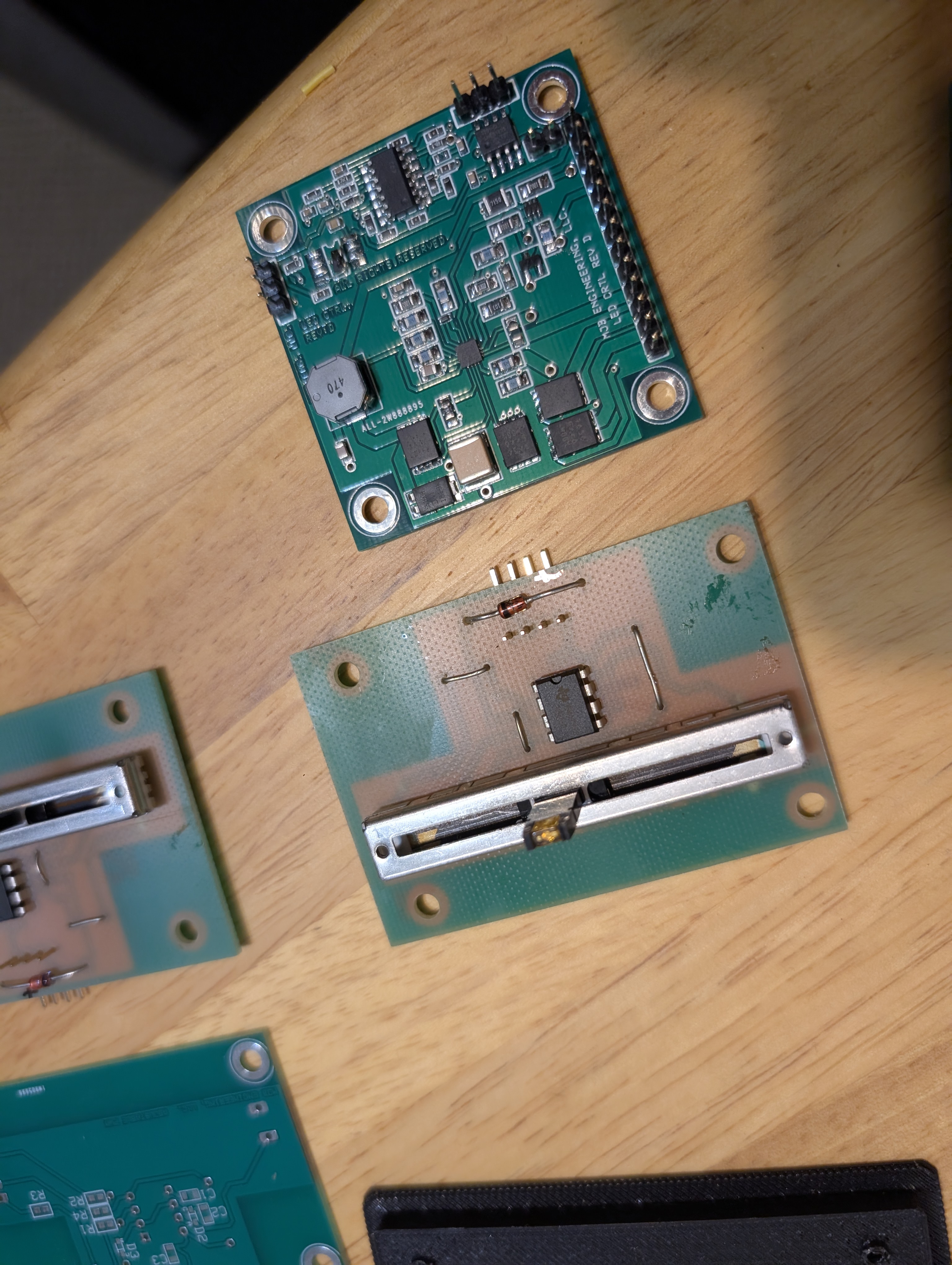

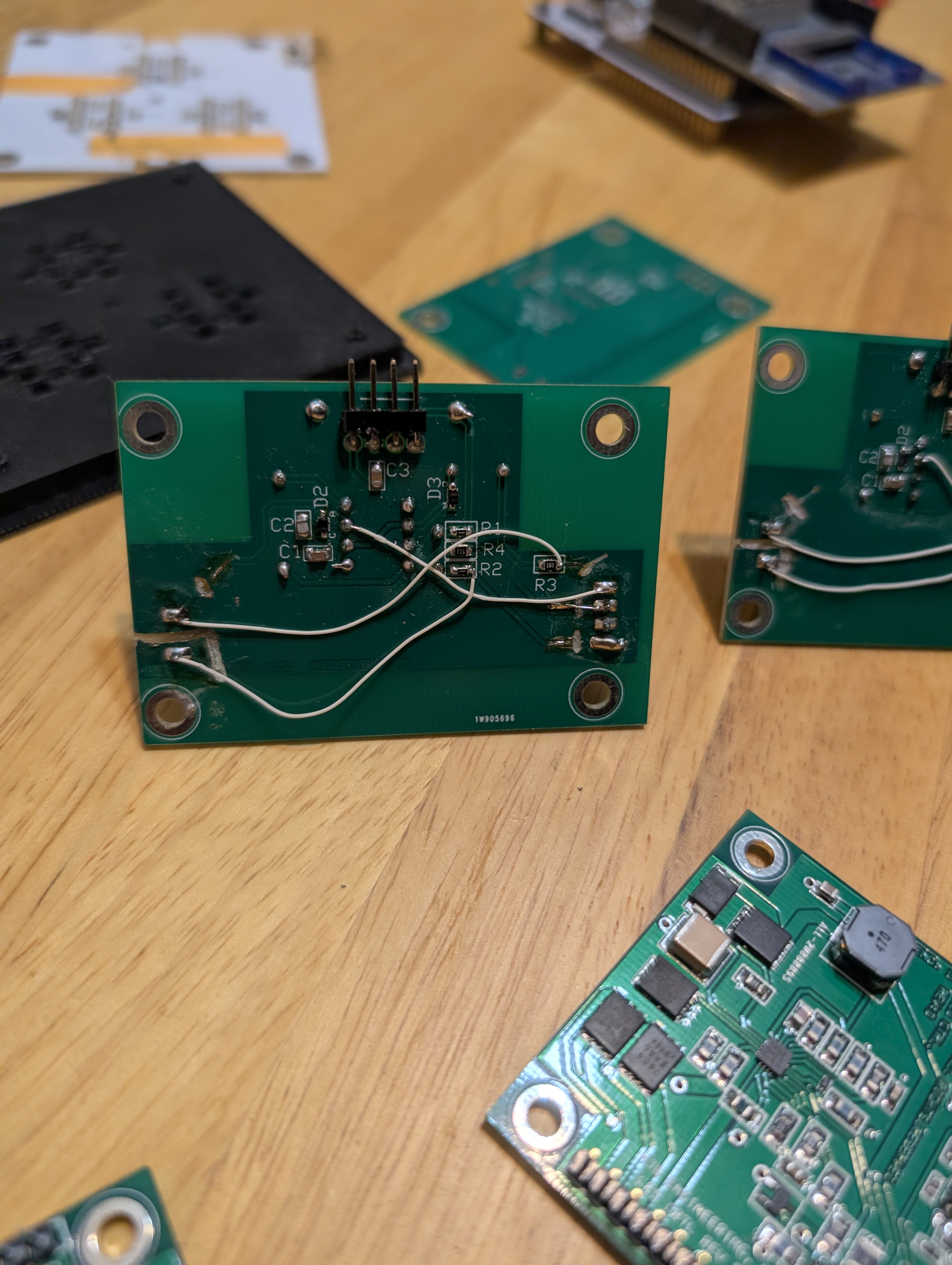

Above is the UV LED array. The shop we used, at the time were coming out with diffusing light pipes. We were considering going with a custom design of their resin made light diffusers, but we also considered utilizing a collumnator lens that would fit atop of this. This would've raised the price, but would've been up there with the rest of the players. Below you can see an example of a collumnator lens ontop of UV LEDs. This conincided with the machine we were designing and reverse engineering, to run lens error correction for clients. Its original design, is an old Kesington Labs semiconductor manufacturing machine, which is extremely accurate. Unfortunately, the CEO of this company admitted there exists no technical documentation of these devices any longer.

After creating a 3D printed "negative" of the UV array, we were able to use this as a holder for small UV LED parts, making the building and soldering process more easy.

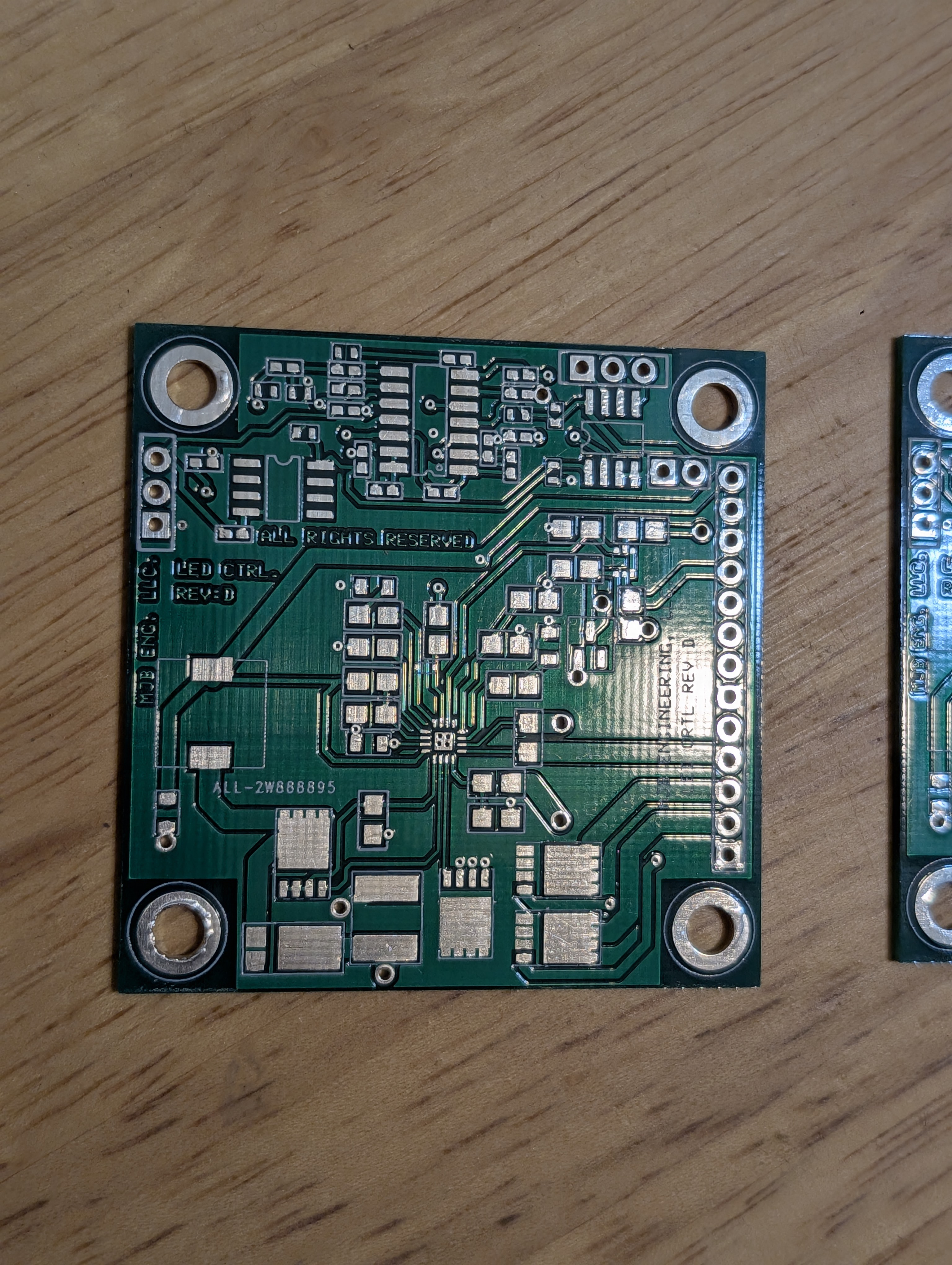

Above is the UV LED Array driver, on the left. To the right, is a dial so that way we would be able to modulate the LEDs on the fly, it is a prototype after all. We had ordered different wavelengths, 390 - 400 nm, 400 - 405 nm, 410 nm - 420 nm and 420 nm - 425 nm. They're all rated for 3.4 V at 500 mA. We were going to try light pipes, which is a much more cheap solution for creating a UV backlight for a LCD screen. At the time, E-Wave Corporation was starting manufacturing their own light pipes. The alternative, would be moving the UV array further away from the LCD / resin vat, and using a custom collumator lens. That would be the more expensive option, you can see below, a picture of a collumator lens used on a UV LED array for a resin 3D printer.