FDM Printing

Capabilities in FDM Printing

Versatile FDM 3D Printing

These prints offer superior strength and durability that resin printing can't match, ideal for functional items and everyday use. I've experimented with various filaments like water soluble PVA, PLA, PC-CF, ASA, PLA+, PETG, Nylon, HIPS and ABS. While resin provides finer details, FDM is better for parts that need to withstand stress.

FDM Printing Projects

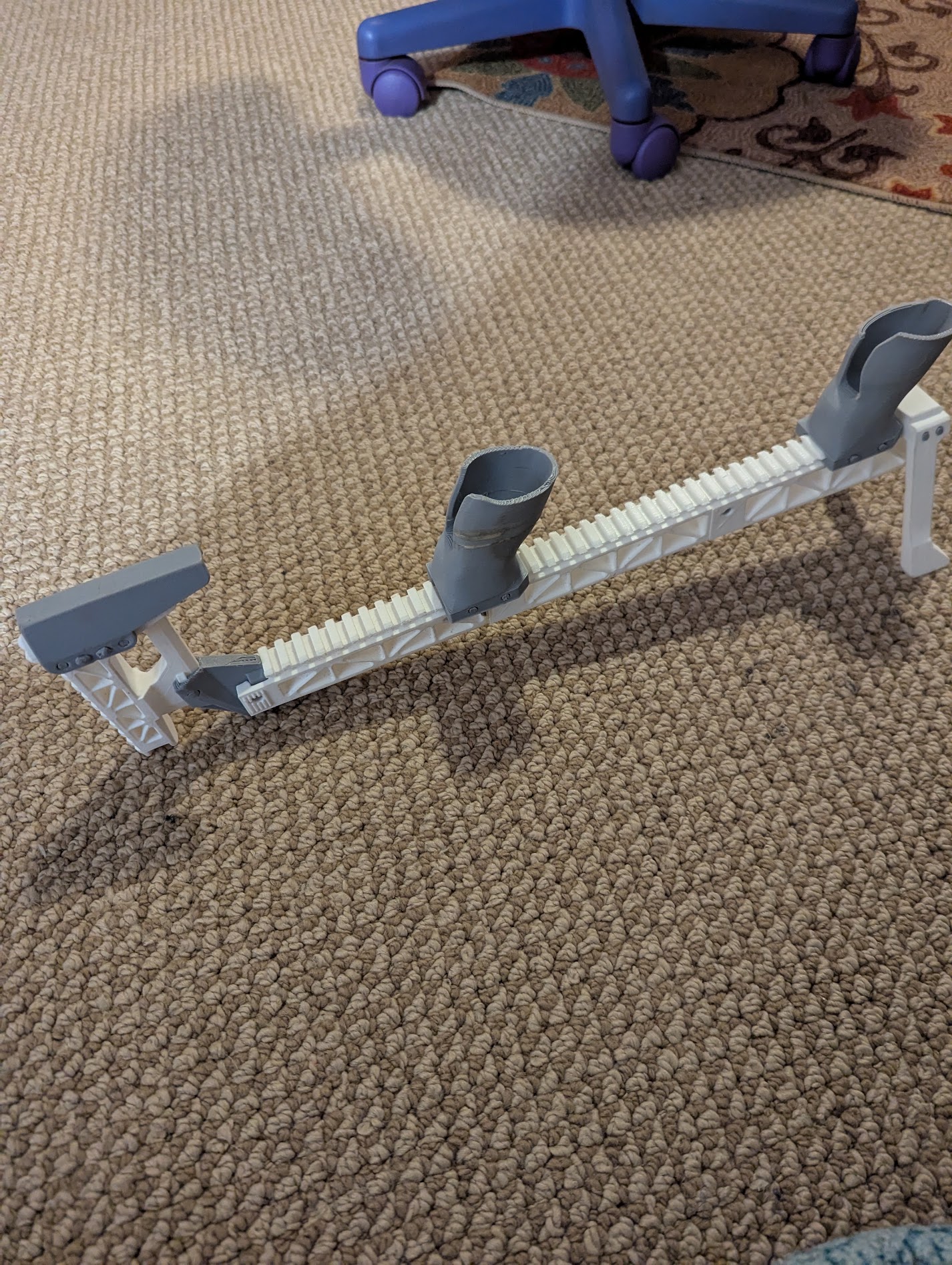

E3D Volcano Hotend

My favorite hotend, of all time, tested through time. This allows anywhere from 0.1mm to 1.2mm nozzles. I usually went with 0.6 or 0.8mm, and this allows for faster printing speeds. The hotend's wide nozzle enables a longer heat-break channel where the filament stays molten. This is now a design adopted by fast printing printers. I created a custom x carriage to hold the e3d hotend on the smooth rods, and also the fan ducts for parts cooling. I went with two fans due to the fast output, allowing faster and better cooling, which is important for the next layer.

The minifigure helicopters below were custom made for a business, "Heli-Co" out of New Orleans. They used these to display the prices of their swag inside their shop.

The fifth image is a FDM printed Eevee, you may select the photo or this text to see a resin print comparison.

Above, the two photos on the left hand side are another great practical use for 3D Printing. These were printed in white PLA+. Due to some pressure washing, we accidentally broke the trim on the railing for a deck outside. The 3D prints have lasted about 5 years so far, and they still look great, with no warping even with record heat temperatures over the Summer.

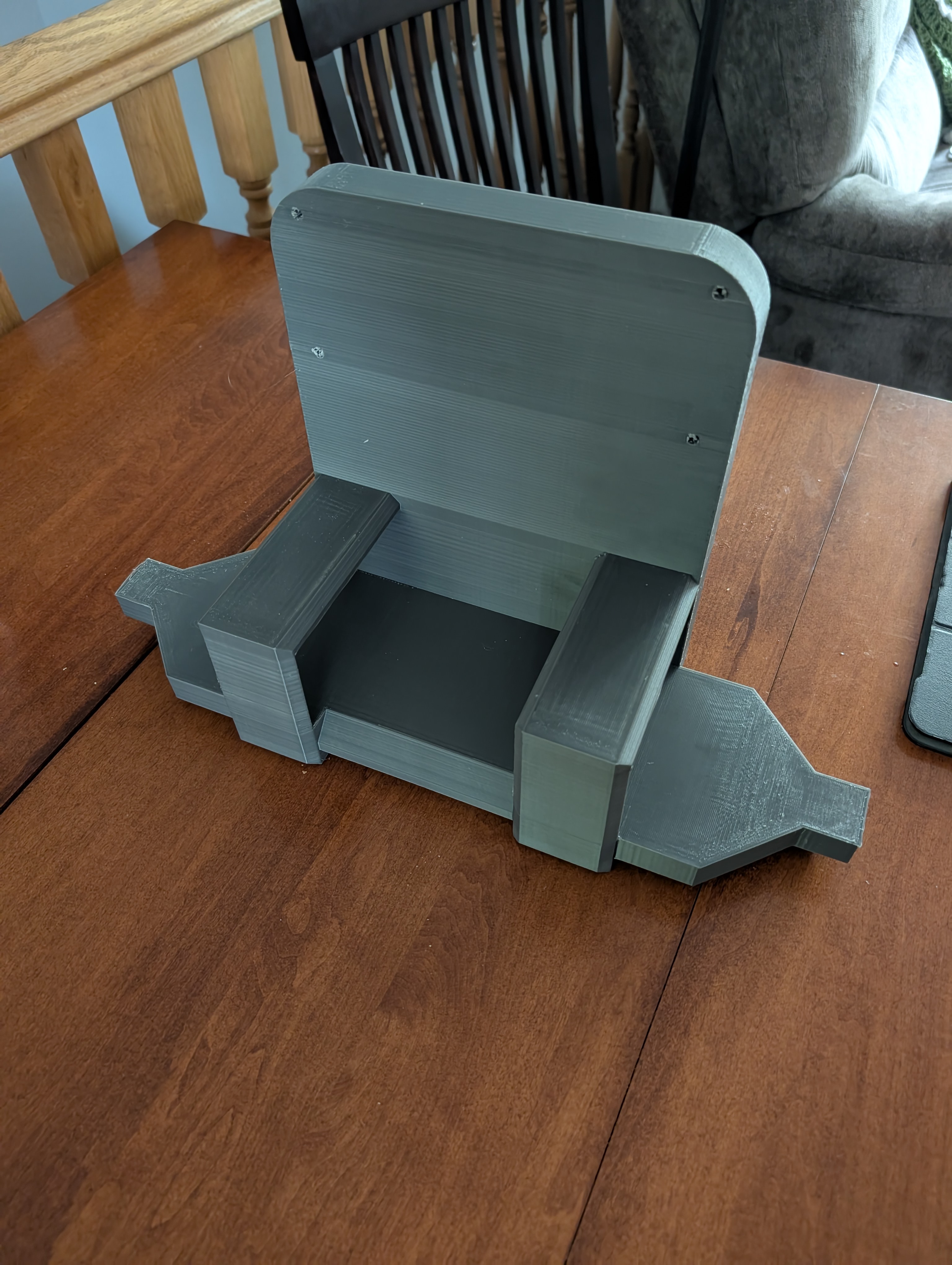

Soundbar Mount

This is a soundbar mount that is VESA compatible to the back of the TV. Now, whenever we decide to watch TV (which we normally do as a family), the soundbar will point along with the picture on the TV. This print comes in around third place for one of the largest prints I made. I am glad I measured not just twice, but three times. The tolerances are quite snug, and the 3D print certainly holds the soundbar very securely. I also took the opportunity when I was designing this 3D Print, to learn more about part stress simulation. You may read more by clicking on this text, under the "Soundbar Mount" section. This was an 18 hour print, requiring a higher amount of infill to ensure rigidity. The last thumbnail above, is the 18 hour timelapse of the printing.

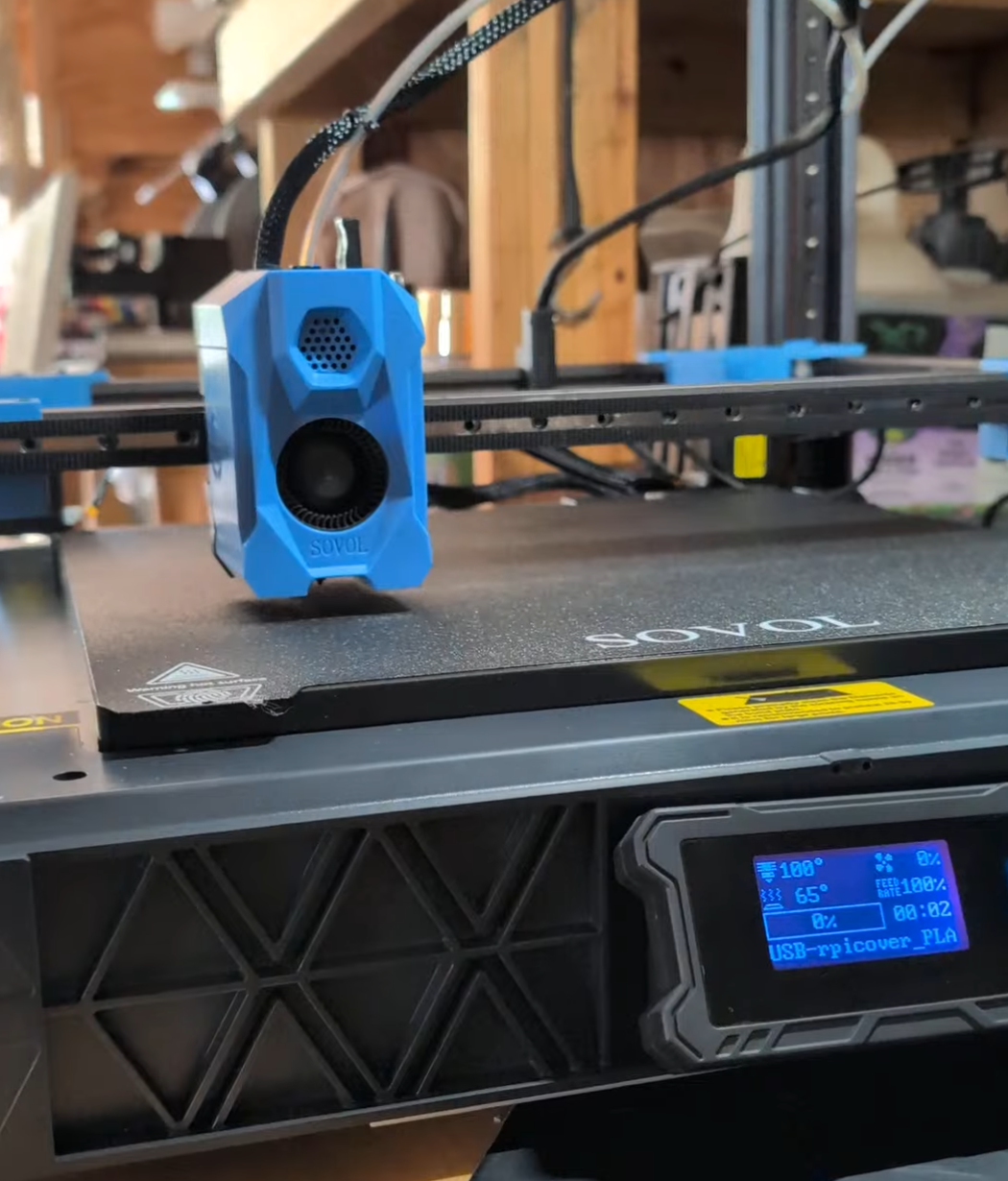

Klipper

Open Source 3D Printer

The object in the timelapse is using wood filament, and it is meant to be a vase for flowers. The ghost is some Halloween lawn decorations, and it is nearly 350mm tall or over 13 inches. That was my tallest print yet. I was able to pick up a filament dryer so that way I can use filaments I've had for nearly a decade, that have just been soaking up moisture.

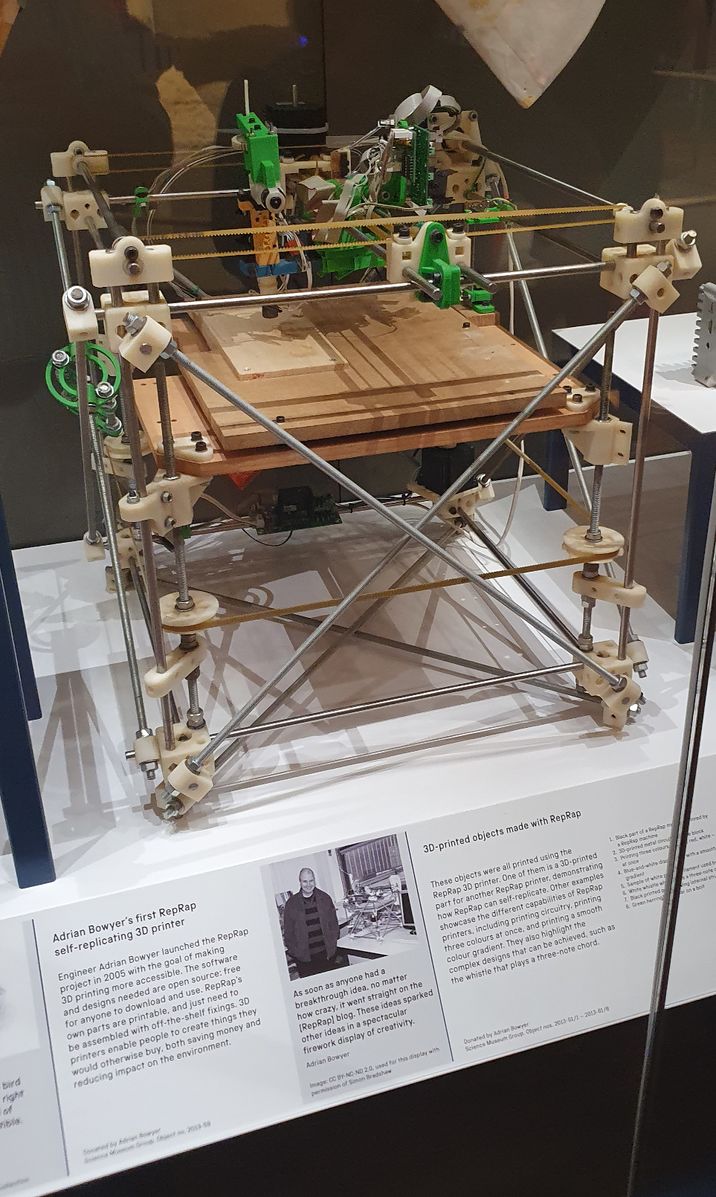

Klipper is an amazing firmware, or firmware interface. I had run it on my previous machines you can see in the photos in the previous sections, and the newer device also runs it as well. This allows me to print approximately 7-10 times faster than conventional 3D printers, which only go about 50-90 mm/s. 3D Printers, open source and proprietary have come an insanely long way. In the early 2000s, 3D printers were thousands if not tens of thousands of dollars. Thankfully, due to some engineers, they came up with the RepRap. This was a collection of screw rods, rods, nuts and bolts with 3D Printed parts, putting together a 3D Printer. RepRaps are general purpose self-replicating manufacturing machines.

The photo above is actually in the Science Museum of London. This is purportedly the "first" RepRap machine.