Resin Printing

Capabilities in Resin Printing

High-Detail Resin 3D Printing

Specializing in resin-based 3D printing for intricate details, such as miniatures and prototypes. Using advanced DLP printers to achieve fine resolutions and smooth surfaces, with a special cleaning post-process using an ultrasonic cleaner before curing.

High resolution prints

These prints capture intricate details that FDM printing can't match, ideal for gaming and collectibles or where precision is needed. In the third image, you can see an almost tie-dye like color scheme. I was doing experimentations with alcohol inks in translucent clear resin. Unfortunately, FDM outmatches resin plastics in strength and durability. While there are some special engineering resins available that boast strength, there is quite a ways to go to match.

Select the Pokemon Evee, or this text, to see a direct FDM comparison.

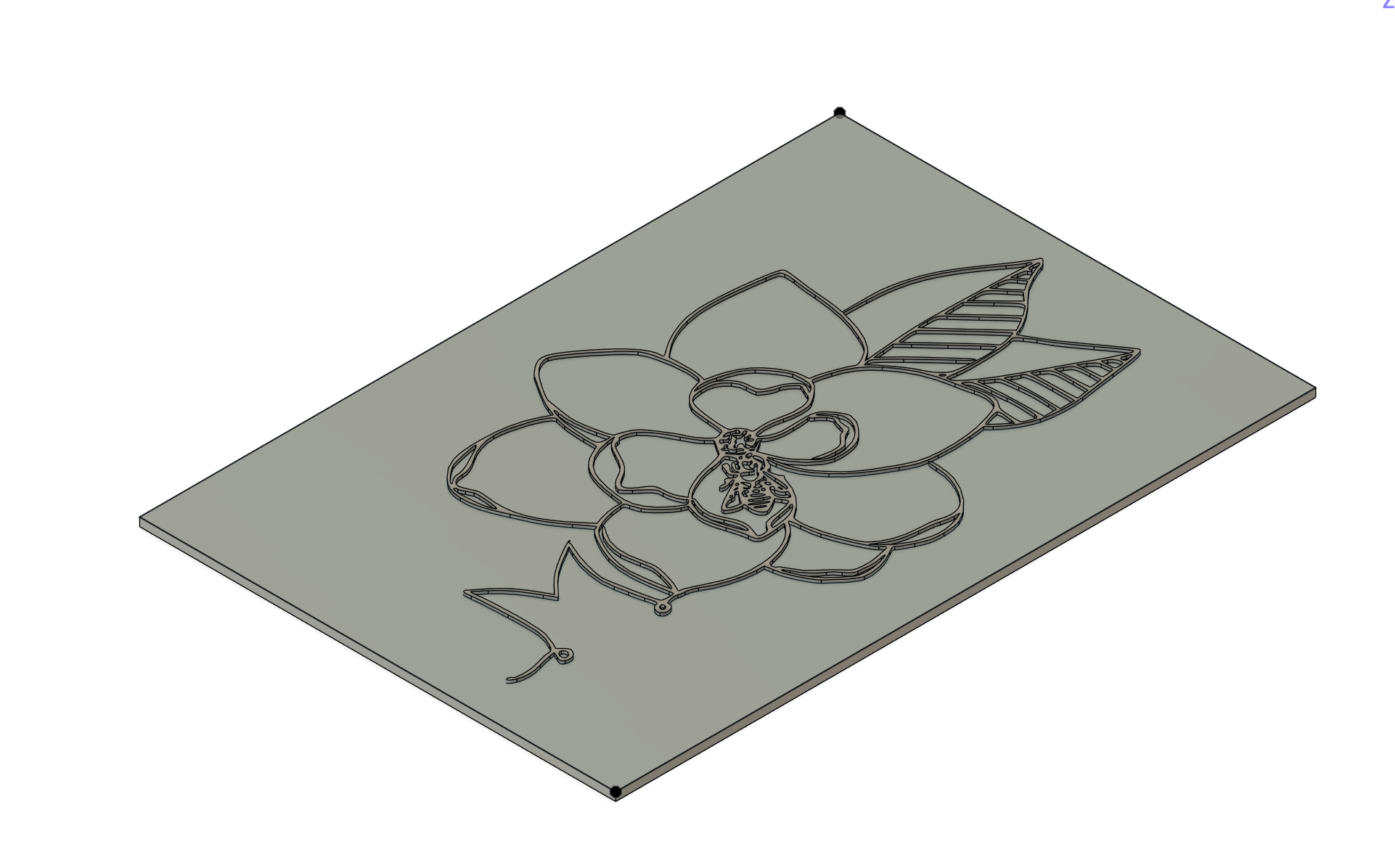

This image above is some artwork from an artist that I had scanned, and vectorized. I then printed it on the resin 3D printer, which provided no surface defects whatsoever. Though, I did do FDM and it was fine too, but more slow. The print, about the size as a A4 piece of paper, was glued to a wooden block, and then dipped or painted with ink, and placed onto either canvas or high quality paper to make prints. I came up with this idea after studying Print Blocks and how Print Presses used to work. While it is not quite a Print Block, it is more closely to a Linocut.

Metal Casting

The high resolution was great for making high accuracy molds, while there still is some variance due to pouring, the heat and cool down of the metal, it still provides a great solution for casting, or even loss casting. While I don't have the equipment such as a vaccuum chamber, or even using investment powder. I found that using sand casting was a great, easy way to make metal parts. I melted down a lot of 6061 Aluminum, recycling soda cans, making around 10 aluminum ingots.